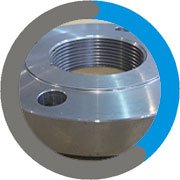

- Inconel X-750 Flanges manufacturer, Inconel X-750 Slip On Flange, Inconel X-750 Welding Neck Flange, Inconel X-750 Blind Flange, Inconel X-750 Socket Weld Flanges

Inconel X-750 Flanges Manufacturers In India

ASTM B564 UNS N07750,Inconel X-750 Flanges,Inconel X-750 Flanges Suppliers,Inconel X-750 Flanges Manufacturers in India,WNR 2.4669 Weld Neck Flanges Exporter in Thailand, Alloy X-750 Orifice Flanges Manufacturer in india.

Inconel x-750 Flanges manufacturer, Inconel x-750 Slip On Flange, Inconel x-750 Welding Neck Flange, Inconel x-750 Blind Flange, Inconel x-750 Socket Weld Flanges,UNS N07750 Inconel X-750 Flange,2.4669 Inconel X-750 Flange, Inconel x-750 Plate Flange, Inconel x-750 Collar Flange, Inconel x-750 Threaded Flange Manufacturers in India. ANSI/ASME B16.5,B16.47,B16.47,B16.36, B16.48 Inconel x-750 Flanges Suppliers & Manufacturer

Inconel x-750 Flanges manufacturer, alloy x-750 flanges, inconel alloy x-750 flanges, ASTM b564 Inconel x-750 Flanges, Inconel x-750 Flanges suppliers, Seamless/Seam Welded Inconel x-750 Flanges, Fabricated Inconel x-750 Flanges Manufacturer & Exporter

Contents

- ASTM B564 Inconel X-750 Flanges Specification

- What is ASTM B564 Inconel X-750 Flanges?

- ASTM B564 Inconel X-750 Flanges Properties

- Our Live Stock of ASTM B564 Inconel X-750 Flanges

- ASTM B564 Inconel X-750 Flanges Price

- ASTM B564 Inconel X-750 Flanges Application

- Types Of ASTM B564 Inconel X-750 Flanges

- Leading manufacturer of ASTM B564 Inconel 601 Flanges

- Useful Info

- Our Sales Network

ASTM B564 Inconel X-750 Pipe Flanges Equivalent Grades

| Standards | Inconel X-750 |

| UNS | N07750 |

| Werkstoff Nr. | 2.4669 |

X-750 Inconel Plate Flanges Specification

| Product name | Inconel X-750 Flanges |

|---|---|

| Specification | ASTM / ASME SB 564 / 160 / 472 |

| Inconel UNS Grade | Inconel 600 (UNS N06600, Alloy 600, 2.4816), Inconel 601 (UNS N06601, Alloy 601, 2.4851), Inconel 625 (UNS N06625, Alloy 625, 2.4856), Inconel 800 (UNS N08800, Alloy 800) |

| Flanges Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | ½" to 36" |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

Inconel UNS N07750 Flanges Chemical Composition

Alloy |

% |

Ni |

Cr |

Fe |

Nb |

Co |

C |

Mn |

Si |

S |

Cu |

Al |

Ti |

Inconel X-750 |

Min. |

|

14 |

5.0 |

0.7 |

|

|

|

|

|

|

0.4 |

2.25 |

Max. |

70 |

17 |

9.0 |

1.2 |

1.00 |

0.08 |

1.00 |

0.5 |

0.01 |

0.5 |

1.0 |

2.75 |

Inconel Alloy WERKSTOFF NR. 2.4669 ASME, DIN, BS, EN Flanges Mechanical Properties

Alloy |

Tensile strength |

Yield strength |

Elongation |

Brinell hardness HB |

Solution treatment |

1267 |

868 |

25 |

≤400 |

| Specification | ASTM B366, ASTM SB 366, ASTM B564, ASME SB564 |

| Grade | ASTM B564 Inconel 600 (UNS N06600, Alloy 600, 2.4816), Inconel 601 (UNS N06601, Alloy 601, 2.4851), Inconel 625 (UNS N06625, Alloy 625, 2.4856), Inconel 800 (UNS N08800, Alloy 800) |

| Connect Type/ Flange Face Type | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ), Lap-Joint Face (LJF), Large Male-Female (LMF), Small Male-Female (SMF), Large Tongue & Groove, Small Tongue, Groove |

| Surface treatment | Anti-rust oil, transparent/ yellow/ black anti trst paint, Zinc, hot dipped galvanized |

| Size Range | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Pressure | DIN:PN6 PN10 PN16 PN25 PN40; ANSI: class: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-PN6, PN10, PN16, PN25, PN40, PN64 etc. JIS: 5K, 10 K, 16 K 20 K,30 K,40 K, 63 K; |

| Standard | ANSI DIN,GOST,JIS,UNI,BS,AS2129,AWWA,EN,SABS,NFE etc. ANSI Flange, ASME Flange, BS Flange, DIN Flange, EN Flange

|

| Production technique: |

|

| Special design | As per your drawing

AS, ANSI, BS, DIN and JIS ASTM B564 Inconel X-750 Threaded Flange, Slip-On Flange, Socketweld Flange, Weld Neck Flange, Blind Flange |

| Test | Direct-reading Spectrograph,Hydrostatic testing machine,X-ray detector,UI trasonic flaw detector,Magnetic particle detector |

| Equipment | Press machine ,Bending machine,Pushing Machine,electric bevelling machine Sand-blasting machine,etc |

| Origin | West Europe / Japan / Indian / USA / Korean |

| Test Certificates | Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report |

| Specialized manufacturer of | ASTM B564 Inconel X-750 Blind Flanges, ASTM B564 Inconel X-750 Table Flanges, ASTM B564 Inconel X-750 Weld Neck Flanges, ASTM B564 Inconel X-750 Threaded Flanges, ASTM B564 Inconel X-750 Slip-On Flanges, ASTM B564 Inconel X-750 Socketweld Flanges, ASTM B564 Inconel X-750 Plate Flanges, ASTM B564 Inconel X-750 Lap Joint Flanges, ASTM B564 Inconel X-750 Loose Flanges, and ASTM B564 Inconel X-750 Orifice Flanges. ASTM B564 Inconel X-750 AS 4087 Water Flanges are available in class 150, 300, 600, 900, 1500 and 2500. |

| Key markets and industries for ASTM B564 Inconel X-750 Flanges |

|

| Reason to choose ASTM B564 Inconel X-750 Pipe Flanges, Key properties |

|

| Similar Pipe Fittings Key grades |

|

Standards/ Types And Pressure Class – B564 Inconel X-750 Flanges

| ASME/ANSI B 16.5 | Welding Neck Flange, Slipon Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, Lap Joint Flange, Threaded Flange, Ring Type Joint Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Welding Neck Flange, Blind Flange [Series A & B] |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Welding Neck Flange, Slipon Flange, Threaded Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Welding Neck Flange, Hubbed Slipon Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, Plate Flange,Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Welding Neck Flange, Socket Welding Flange, Slip-On Flange, Blind Flange,Screwed Boss Flange, Lapped Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636,2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

ASTM B564 Inconel X-750 Flanges Type / Size Range

We produce the size range DN15 – DN2500, according to the respective valid norm.

For larger dimensions or dimensions outside the standards please contact us directly

|

Type

|

Dimension range *

|

Drawing**

|

|

ASTM B564 Inconel X-750 Blind Flanges

ASTM B564 Inconel X-750 Blind Flanges |

DN15 – DN2500

½ “- 24″ |

DIN2527 PN16 DN150 BL 300lb 6 “

|

|

ASTM B564 Inconel X-750 Threaded with neck

ASTM B564 Inconel X-750 Threaded Flanges |

DN15 – DN150

½ “- 24″ |

DIN2566 DN32 / 42.4 TH 300lb 1 “

|

|

Flanges smooth for welding

|

DN15 – DN2500

|

DIN2576 DN150

|

|

ASTM B564 Inconel X-750 Welding neck

ASTM B564 Inconel X-750 Welding Neck Flanges |

DN15 – DN2500

½ “- 24″ Dy10 – Dy2400 |

DIN2635 DN150 / 168.3 WN 300lb 6 “GOST Dy150 Py16

|

|

ASTM B564 Inconel X-750 loose flanges, smooth Bunde

|

DN15 – DN2500

|

DIN2642 DN150

|

|

ASTM B564 Inconel X-750 loose flanges Stub

|

DN15 – DN2500

|

DIN2673 DN150

|

|

ASTM B564 Inconel X-750 Welding flanges with neck

ASTM B564 Inconel X-750 Slip On Flanges |

DN15 – DN2500

½ “- 24″ Dy10 – Dy2400 |

DIN86030 DN150

SO 300lb 6 ” GOST |

|

ASTM B564 Inconel X-750 Lap Joint Flanges

|

½ “- 24″

|

LJ 300lb 6 “

|

|

ASTM B564 Inconel X-750 Socket Welding Flanges

|

½ “- 3″

|

SW 300lb 6 “

|

Types Of ASTM B564 Inconel X-750 Flanges

B564 Inconel X-750 Weld Neck Flanges Manufacturers

ASME SB564 Inconel X-750 RTJ Flanges Stockiests

Inconel X-750 Threaded Flanges Distributors

Inconel X-750 Alloy SWRF Flanges

Top Quality Inconel X-750 Socket weld Flanges

X-750 Alloy Inconel Orifice Flanges Exporters

ASTM B564 Inconel X-750 DIN Flanges

ASTM/ASME Inconel Alloy X-750 Forged Flanges

Incoloy Alloy X-750 Flanges

X-750 Incoloy Blind Flanges

X-750 Inconel Blind Flanges

Inconel x-750 Lap Joint Flange

Inconel x-750 Socket Weld Flanges

Inconel x-750 Threaded Flange

Inconel x-750 Reducing Flange

Inconel x-750 Square Flange

Inconel x-750 Expander Flange

Inconel x-750 Groove & Tongue Flange

Inconel x-750 Spades Ring Spacers Flange

Inconel x-750 Screwed Flange

Inconel x-750 Flange Facing Type & Finish

Inconel x-750 Collar Flange

Inconel x-750 Flat Face Flange

Inconel x-750 Raised Face Flanges

ASTM B564 Inconel X-750 Slip On Flanges

Inconel UNS N06X-750 Pipe Flanges

ASTM B564 Incoloy X-750 Slip On Flanges

Incoloy UNS N08X-750 Pipe Flanges

ASTM B564 Incoloy X-750 BLRF Flanges Manufacturers

B564 Incoloy X-750 Weld Neck Flanges Manufacturers

ASME SB 564 Inconel X-750 RTJ Flanges Stockiests

Incoloy X-750 Threaded Flanges Distributors

Incoloy X-750 Alloy SWRF Flanges

Top Quality Incoloy X-750 Socket weld Flanges

X-750 Alloy Incoloy Orifice Flanges Exporters

ASTM B564 Incoloy X-750 DIN Flanges

ASTM/ASME Incoloy Alloy X-750 Forged Flanges

Inconel Alloy X-750 Flanges

X-750 Inconel Blind Flanges

Inconel X-750 Alloy Screwed Flanges Dealers

ASTM B564 Alloy Inconel X-750 SORF Flanges

Inconel X-750 Plate Flanges Stockholder

Inconel x-750 Slip On Flange

Inconel x-750 Welding Neck Flange

Inconel x-750 Long Welding Neck Flange

Inconel x-750 Blind Flange

ASME SB564 Inconel X-750 RTJ Flanges Stockiests

ASTM B564 Inconel X-750 Slip On Flanges

Inconel UNS N06X-750 Pipe Flanges

ASTM B564 Inconel X-750 BLRF Flanges Manufacturers

X-750 Inconel Alloy WNRF Flanges Suppliers

B564 Inconel X-750 Spectacle Blinds Flanges Suppliers

ASME SB 564 Inconel X-750 Flanges

AISI Inconel X-750 ASTM B564 Flanges

Inconel x-750 Ring Type Joint Flange

Inconel x-750 Spectacle Blind Flanges

Inconel x-750 Plate Flange

Inconel x-750 Flat Flange

Inconel x-750 Orifice Flange

Inconel x-750 Weldo / Nipo Flange

Inconel x-750 Loose Flange

Inconel x-750 High Hub Blinds Flange

Inconel x-750 Weld Neck Flange Series A or B

Inconel x-750 Lip type flange

Inconel x-750 Puddle Flange

ASTM B564 Inconel X-750 Alloy Loose Flanges

Inconel X-750 Flange JIS Standard Flanges

X-750 Inconel Ring Type Joint Flanges Stockiest in India

Inconel Alloy X-750 Reducing Flanges

ASTM B564 Inconel X-750 Lap Joint Flanges

Inconel WERKSTOFF NR .2.4816 Long Weld Neck Flanges

Inconel X-750 Alloy Screwed Flanges Dealers

ASTM B564 Alloy Inconel X-750 SORF Flanges

Inconel X-750 Plate Flanges Stockholder

X-750 Inconel Alloy WNRF Flanges Suppliers

B564 Inconel X-750 Spectacle Blinds Flanges Suppliers

ASME Inconel X-750 SB 564 Flanges

AISI Inconel X-750 ASTM B564 Flanges

ASTM B564 Inconel X-750 Alloy Loose Flanges

Inconel X-750 Flange JIS Standard Flanges

X-750 Incoloy Ring Type Joint Flanges Stockiest in India

Incoloy Alloy X-750 Reducing Flanges

ASTM B564 Incoloy X-750 Lap Joint Flanges

X-750 Inconel Ring Type Joint Flanges Stockiest

Inconel Alloy X-750 Reducing Flanges

ASTM B564 Inconel X-750 Lap Joint Flanges

Inconel WERKSTOFF NR. 2.4856 Long Weld Neck Flanges

ASTM B564 Inconel X-750 Flanges?

Ranflex Metals is one of the Leading Manufacturer, Supplier and Exporter Of Inconel X-750 Flanges is a nonmagnetic nickel-chromium alloy with properties that include high temperature strength comparable to 18-8 alloys and high resistance to organic and inorganic corrosives. X-750 Inconel Alloy WNRF Flanges Suppliers, B564 Inconel X-750 Spectacle Blinds Flanges Suppliers, ASME SB 564 Inconel X-750 Flanges, AISI Inconel X-750 ASTM B564 Flanges, ASTM B564 Inconel X-750 Alloy Loose Flanges, Inconel X-750 Flange JIS Standard Flanges, X-750 Inconel Ring Type Joint Flanges Stockiest in India, Inconel Alloy X-750 Reducing Flanges, ASTM B564 Inconel X-750 Lap Joint Flanges, Inconel WERKSTOFF NR .2.4816 Long Weld Neck Flanges, Inconel X-750 Alloy Screwed Flanges Dealers, ASTM B564 Alloy Inconel X-750 SORF Flanges, Inconel X-750 Plate Flanges Stockholder, X-750 Inconel Alloy WNRF Flanges Suppliers, B564 Inconel X-750 Spectacle Blinds Flanges Suppliers, ASME Inconel X-750 SB 564 Flanges, AISI Inconel X-750 ASTM B564 Flanges, ASTM B564 Inconel X-750 Alloy Loose Flanges, Inconel X-750 Flange JIS Standard Flanges , X-750 Incoloy Ring Type Joint Flanges Stockiest in India, Incoloy Alloy X-750 Reducing Flanges, ASTM B564 Incoloy X-750 Lap Joint Flanges, X-750 Inconel Ring Type Joint Flanges Stockies,t Inconel Alloy X-750 Reducing Flanges, ASTM B564 Inconel X-750 Lap Joint Flanges, Inconel WERKSTOFF NR. 2.4856 Long Weld Neck Flanges, Inconel X-750 Alloy Screwed Flanges Dealers, ASTM B564 Alloy Inconel X-750 SORF Flanges, Inconel X-750 Plate Flanges Stockholder,

ASTM B564 Inconel X-750 Pipe Flanges Application

- ASTM B564 Inconel X-750 Flanges uses in Oil and Gas Pipeline

- ASTM B564 Inconel X-750 Flanges uses in Chemical Industry

- ASTM B564 Inconel X-750 Flanges uses in Plumbing

- ASTM B564 Inconel X-750 Flanges uses in Oil & Gas Industry

- ASTM B564 Inconel X-750 Flanges uses in Water Supply Systems

- ASTM B564 Inconel X-750 Flanges uses in Paper & Pulp Industry

- ASTM B564 Inconel X-750 Flanges uses in Power Plant

- ASTM B564 Inconel X-750 Flanges uses in Fabrication Industry

- ASTM B564 Inconel X-750 Flanges uses in General purpose applications

- ASTM B564 Inconel X-750 Flanges uses in Food Processing Industry

- ASTM B564 Inconel X-750 Flanges uses in Structural Pipe

- ASTM B564 Inconel X-750 Flanges uses in Heat Exchangers

Available Inconel Flanges Grades

Leading manufacturer of ASTM B564 Inconel X-750 Flanges

We also having Stock of ASTM B564 Inconel X-750 Flanges & other Stainless Steel Flanges, Carbon Steel Flanges, Alloy Steel Flanges manufactured by :

| Erne Fittings, Austria | Metal far, Italy | Lame S.R.l., Italy |

| BENKAN Corporation, Japan | BKL- Thai Benkan, Thailand | TecnoForge, Italy |

| Ulma, Spain | Mega, Italy | Melesi, Italy |

| Interfit, France | Raccortubi S.P.A., Italy |

Our Live Stock of ASTM B564 Inconel X-750 Flanges Supplied by Ranflex Metals

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inconel X-750 Flanges At Best Price

-

high temperature nickel inconel alloy x-750 for flanges

FOB Price:US $1-30 Kilogram -

Inconel X-750 Lap ped Flange

FOB Price:US $10-30 Kilogram -

Inconel X-750 / GH4145 stainless steel Welding plate flanges

FOB Price:US $10-100 Kilogram -

GH145/W.Nr.: 2.4669 /UNS N07750/Inconel X-750 Welding Neck

FOB Price:US $10-200 Kilogram -

UNS N07750 super alloy nickel alloy inconel X-750 flange of factory price

FOB Price:US $8-15 Kilogram -

high temperature nickel inconel alloy x-750 flange

FOB Price:US $1-30 Kilogram -

di flange adaptor inconel x-750 insulating flange hastelloy b3 insulating flange

FOB Price:US $1-1000 Kilogram -

W.Nr 2.4669 super alloy nickel alloy inconel X-750 flange of factory price

FOB Price:US $600-1000 Kilogram -

Inconel X-750 slip-on flange

FOB Price:US $1-150 Kilogram -

GH145/W.Nr.: 2.4669 /UNS N07750/Inconel X-750 Blind Flange

FOB Price:US $10-200 Kilogram -

High temperature alloy Inconel X-750 /GH4145 stainless steel Welding plate

FOB Price:US $10-100 Kilogram -

Super alloy nickel inconel X-750 flange of factory price

FOB Price:US $8-15 Kilogram -

super alloy nickel inconel X-750 flange of factory price

FOB Price:US $8-15 Kilogram -

Inconel X-750 welding neck flange

FOB Price:US $1-150 Kilogram

Useful Information:

N07750 | 2.4669 | NICR22MO9NB | NA 21 | ХН75МБТЮ | ЭИ602 | NCF X-750 | NC22DNB4M

ASTM B564 Inconel X-750 is an alloy essentially consisting of nickel, chromium and molybdenum with exceptional resistance to pitting and corrosion cracking. The alloy has extraordinary mechanical properties at immensely low ans high temperatures. The alloy has high rupture and tensile strength with eminent weldability and brazeability. The alloy has excellent corrosion resistance to inorganic acids such as sulfuric acid, hydrochloric acid, phosphoric acid and nitric acid. The immense level of nickel in the alloy empowers it to defy severe corrosive environments such as neutral salts, alkaline media and sea waters.

Scope* :-

This specification2 covers forgings of nickel alloy UNS N02200, Ni-Cu alloy UNS N04400, Ni-Cr-Fe alloys UNS N06600, UNS N06603, and UNS N06690, Ni-Cr-Mo-Nb alloy UNS N06625, Ni-Cr-Mo-Si alloy UNS N06219, low-carbon Ni-Mo-Cr alloys UNS N10276 and UNS N06022, Ni-Cr-Mo-W alloy UNS N06110, low-carbon Ni-Cr-Mo-W alloy UNS N06686, Ni-Fe-Cr-Mo-Cu alloy UNS N08825, Fe-Ni- Cr- Mo-N alloy UNS N08367, low-carbon Ni-Cr-Mo alloys UNS N06035, UNS N06058, and UNS N06059, low carbon Ni-Cr- Mo-Cu alloy UNS N06200, Ni-Mo-Cr-Fe alloy UNS N10242, Ni-Mo alloys UNS N10665 and UNS N10675, low-carbon Ni-Fe-Cr-Mo-Cu alloy UNS N08031, Ni-Cr-W-Mo alloy UNS N06230, Ni-Cr-Co-Mo alloy UNS N06617, Ni-Co-Cr-Si alloy UNS N12160, Ni-Fe-Cr alloys, Ni-Mo alloy UNS N10629, Ni-Cr-Fe-Al alloy UNS N06025, Ni-Cr-Fe-Si alloy UNS N06045, Low-Carbon Ni-Mo- Cr-Ta alloy UNS N06210, Ni- Mo-Cr-Fe alloy UNS N10624, and low-carbon Cr-Ni-Fe-N alloy UNS R20033*

The nickel-iron-chromium alloys are UNS N08120, UNS N08800, UNS N08810, and UNS N08811. Alloy UNS N08800 is normally employed in service temperatures up to and including 1100°F (593°C). Alloys UNS N08810, N08120, and UNS N08811 are normally employed in service tempera tures above 1100°F where resistance to creep and rupture is required, and are annealed to develop controlled grain size for optimum properties in this temperature range.

The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

ASTM Standards

- B 880 Specification for General Requirements for Chemical Check Analysis Limits for Nickel, Nickel Alloys and Cobalt Alloys

- E 8 Test Methods for Tension Testing of Metallic Materials

- E 29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

- E 76 Test Methods for Chemical Analysis of Nickel-Copper Alloys4

- E 112 Test Methods for Determining Average Grain Size

- E 350 Test Methods for Chemical Analysis of Carbon Steel, Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and Wrought Iron

- E 1473 Test Methods for Chemical Analysis of Nickel, Cobalt, and High-Temperature Alloys

Our Sales Network

-

We are Exporter of Inconel X-750 Flanges in Worldwide Such as India, Tibet, Saudi Arabia, Canada, Serbia, Spain, Austria, Iraq, Chile, Lithuania, Taiwan, Libya, Ecuador, India, Thailand, Iran, New Zealand, Poland, Algeria, Colombia, Bulgaria, Qatar, Bhutan, Germany, Australia, Ghana, Indonesia, South Korea, Lebanon, Kazakhstan, Macau, South Africa, Croatia, Israel, Namibia, Kuwait, Estonia, Pakistan, Norway, Czech Republic, Bahrain, Mongolia, Nigeria, Afghanistan, Egypt, Belgium, Bolivia, Vietnam, Jordan, Kenya, Singapore, France, Netherlands, Azerbaijan, Nepal, Romania, China, Slovakia, Angola, Philippines, Belarus, Morocco, Turkey, Greece, Portugal, Switzerland, Hong Kong, Nigeria, Peru, Chile, Iran, United Kingdom, Denmark, Yemen, Bangladesh, Argentina, Russia, Mexico, Malaysia, Italy, Trinidad & Tobago,Tunisia, Japan, Sri Lanka, Brazil, Gabon, Ireland, Puerto Rico, Hungary, United Arab Emirates, Gambia, Sweden, Finland, United States, Venezuela, Oman, Zimbabwe, Costa Rica, Mexico, Ukraine, Poland.

-

We are Suppliers of Inconel X-750 Flanges in India Such as Mumbai, Hanoi, Noida, Chiyoda, Nashik, Ankara, Vadodara, Pimpri-Chinchwad, Chennai, Cairo, Montreal, Perth, Aberdeen, Doha, Karachi, Granada, Rajkot, Calgary, Santiago, New York, Thane, Manama, Riyadh, Tehran, Geoje-si, Hyderabad, Dubai, Moscow, Sydney, Ahmedabad, Ulsan, Singapore, Jakarta, Vung Tau, Melbourne, Al Khobar, London, Navi Mumbai, Ernakulam, Gimhae-si, Ranchi, Algiers, Kuala Lumpur, La Victoria, Courbevoie, Secunderabad, Hong Kong, Haryana, Rio de Janeiro, Dammam, Los Angeles, Al Jubail, Bogota, Kuwait City, Mumbai, Gurgaon, Port-of-Spain, Faridabad, Colombo, Ludhiana, Milan, Abu Dhabi, Dallas, Bangkok, Bhopal, Ahvaz, Ho Chi Minh City, Lagos, Surat, Madrid, Thiruvananthapuram, Busan, Chandigarh, Coimbatore, New Delhi, Sharjah, Houston, Baroda, Istanbul, Howrah, Mexico City, Bengaluru, Lahore, Petaling Jaya, Jeddah, Visakhapatnam, Jaipur, Brisbane, Seoul, Muscat, Kolkata, Indore, Atyrau, Kanpur, Caracas, Edmonton, Toronto, Jamshedpur, Nagpur, Pune.

Our Associate Manufacturer |

||||

Melesi |

Metalfar |

Raccortubi S.p.A. |

TecnoForge |

Ulma |

BENKAN Corporation |

BKL |

Interfit |

Lame S.r.l. |

Mega |